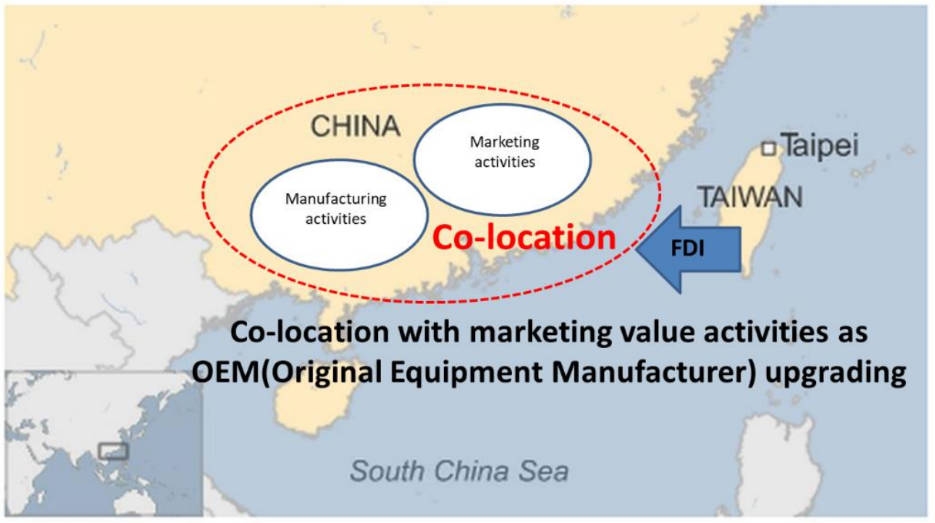

Amid the disruptions brought by COVID-19 and increasing geopolitical tensions, global supply chains are facing unprecedented challenges. Assistant Professor Yu-Yuan Shih from the Graduate Institute of Sustainability Management and Environmental Education at National Taiwan Normal University found that Taiwanese manufacturers in China adopting a “co-location” strategy—integrating marketing and manufacturing at the same site—can significantly enhance local production capabilities and supply chain resilience. Compared to ODM and OBM models, this approach offers greater flexibility and lower marketing costs, allowing companies to respond swiftly in times of crisis and increase global competitiveness. The study also revealed that factors such as international presence, local R&D and marketing networks, and market demand are positively linked to co-location decisions, while the pandemic had a temporary dampening effect, leading firms to adopt more conservative strategies.

In the post-pandemic era, Shih suggests that Taiwanese businesses should strengthen integration between marketing and manufacturing by establishing local centers to accelerate innovation and resource coordination. Increasing marketing agility, fostering local partnerships, and leveraging technologies like AI and data analytics can further improve the effectiveness of this integration. Although the study is limited by the cultural similarities among samples and its focus on manufacturer perspectives, future research could explore diverse cultural settings, stakeholder viewpoints, and the impact of differentiated marketing strategies and technological applications on enhancing supply chain resilience.